Introduction:

Biomass gasification is a process in which the agricultural and forestry wastes such as crop straw, wood, fruit shell and bark are used as raw materials. With the help of air and water vapor, after undergoing pyrolysis, oxidation and reduction reactions, and the raw materials are finally converted into combustible gases such as carbon monoxide, hydrogen and low molecular hydrocarbons, ash (carbon) and other substances. The generated combustible gas can be used for power generation, gas supply, boiler heating and replacing coal combustion; the liquid product vinegar can be used to prepare foliar fertilizer, deodorant, bacteriostatic agent and so on; the solid products (biomass charcoal or ash) can be made into carbon-based fertilizer, activated carbon, barbecue charcoal, etc.

Types of raw materials: wood chips, branches, fruit shells, palms, straws, edible mushroom residues, cattle, sheep and livestock manure, etc. They are from various and wide sources, and cost is low. Both of the pieces or briquettes of the raw materials can be put into the furnace;

Particle size of raw materials:

20~50mm, the maximum is not more than 100, and the raw material with 10mm particle size is not more than 10%;

Moisture content of raw materials:Below 20%;

Gas yield:1.5~2 Nm3/ kg;

Gas calorific:1000~1500kcal/ Nm3 (different raw materials are for different furnace type)

Gasification efficiency:Up to 78%

Our company can provide biomass gasifiers with different structural types and specifications, such as up-suction type, down-suction type and composite type, and can make comprehensive analysis according to the types of local raw materials and supply conditions, market prices and application demands, and customize the most suitable comprehensive technical scheme for customer.

Typical applications

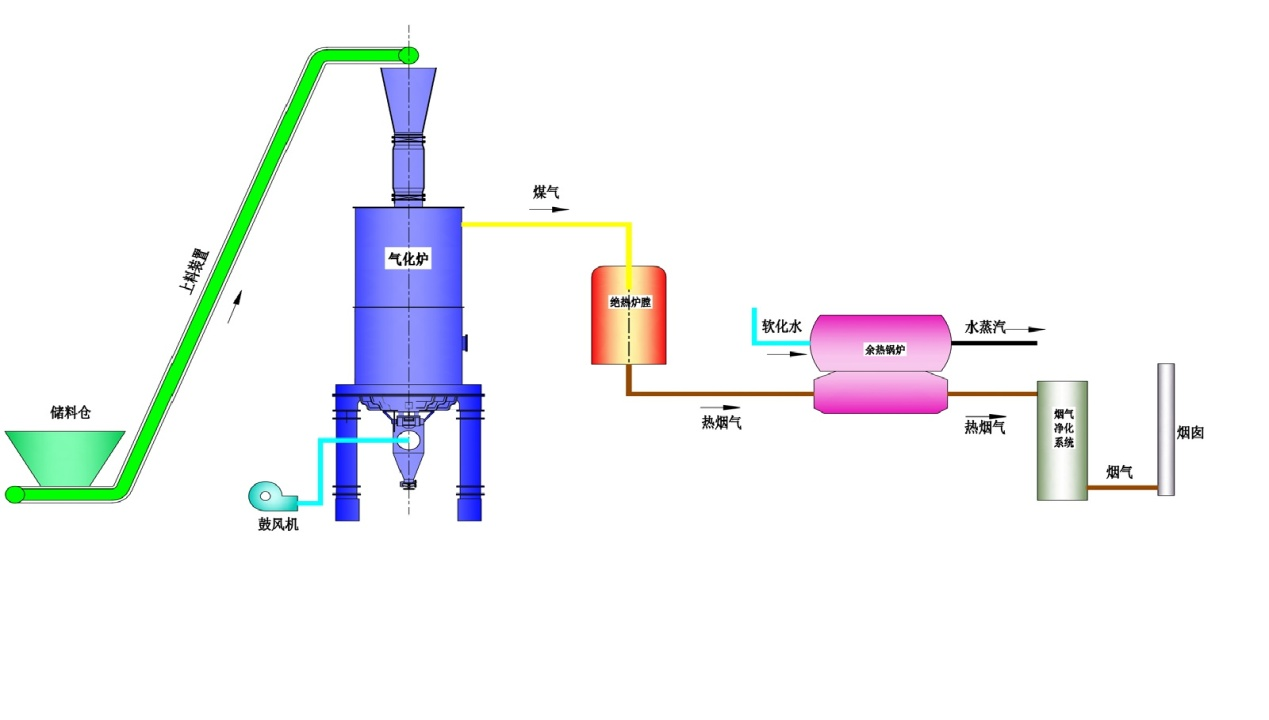

1. Co-production of carbon and heat:

The biomass gas produced by gasifier and hot flue gas produced after combustion, is supplied to waste heat boiler to produce steam or hot water for heating, bathing, industrial steam, etc.

Features:

Hot gas directly enters the adiabatic furnace for combustion. Th process makes full use of the sensible heat of gas, and the heat utilization rate is high ;

The process is simple and the investment in equipment is less;

Biomass resources is rich, the price is low and economy is good;

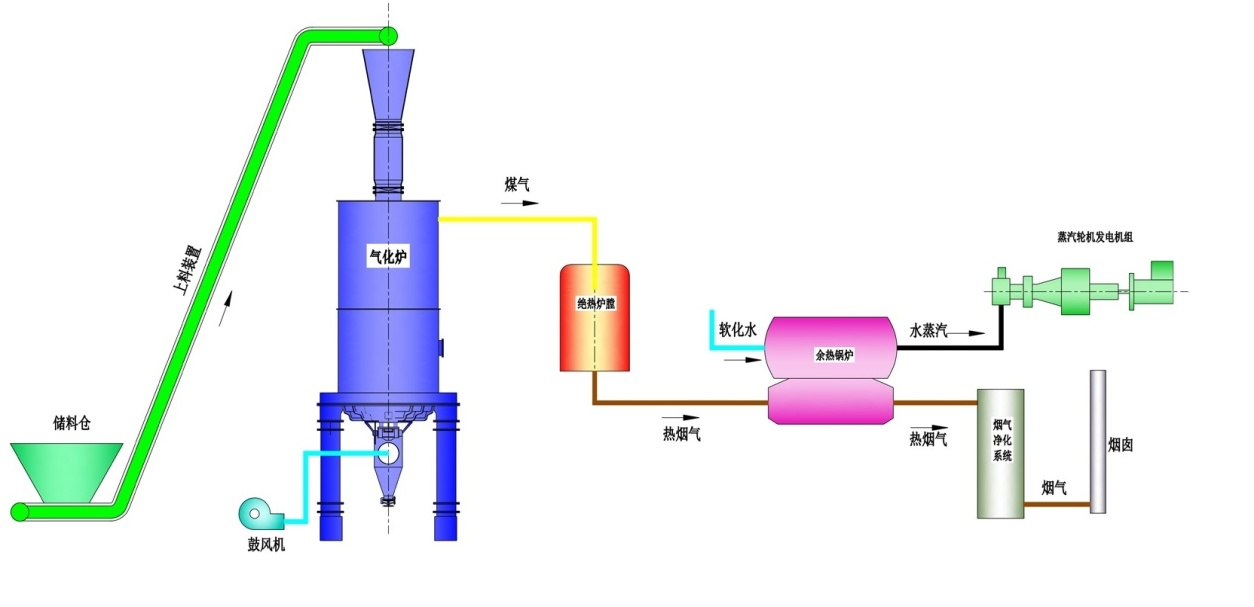

2. Cogeneration of carbon, heat and electricity

Biomass gas produced by gasifier, hot flue gas produced after combustion, is supplied to waste heat boiler to generate steam, and then drives steam turbine generator set to generate electric energy.

Features:

The gasification process is simple, power generation technology is mature, and the investment in equipment is low

Cogeneration of carbon, heat and electricity is more suitable for the areas where there are demands for both the electricity and heating.

3. Cogeneration of carbon, electricity and heat

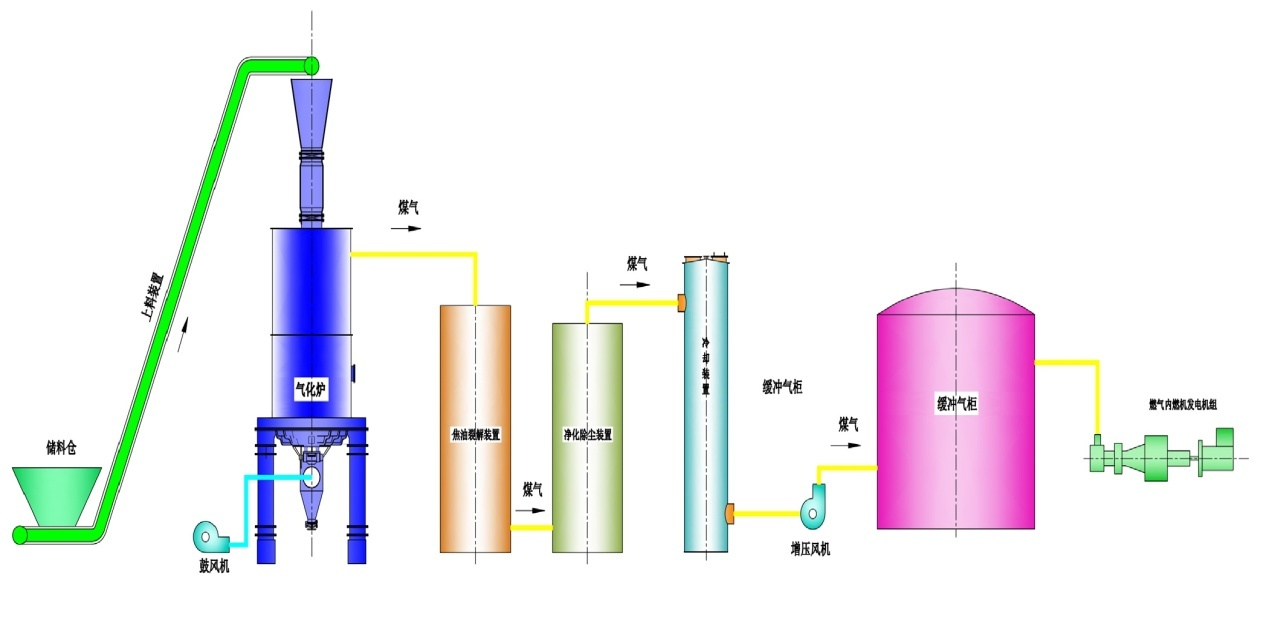

After gasification of the gasifier, the biomass gas produced by the biomass raw materials passes through a purification and cooling device, and tar and dust are removed, then it becomes clean and normal-temperature gas, which can be used for direct power generation by the internal combustion engine. In the waste flue gas generated from internal combustion engine due to combustion and power generation, the heat energy is recycled.

Features:

The temperature at the outlet of the new improved gasifier is high, and the tar is in vapor state, so that it can avoid blocking the outlet pipeline;

The purified tar content is low: less than 50mg/Nm3, and after passing through catalytic cracking device, the tar is converted into small molecule combustible gas, so that improve the output and calorific value of coal gas.

The overall thermal efficiency is high: above 75%;

There are many kinds of by-products: carbon and vinegar. Among them, carbon can be made into carbon-based fertilizer, activated carbon, barbecue carbon and so on; vinegar can be used to prepare foliar fertilizer, deodorant, bacteriostatic agent, etc;

The power generation efficiency of internal combustion engine is relatively high;

The capacity of single machine is small, it is suitable for distributed characteristic towns, industrial parks and residential quarters with insufficient power supply;