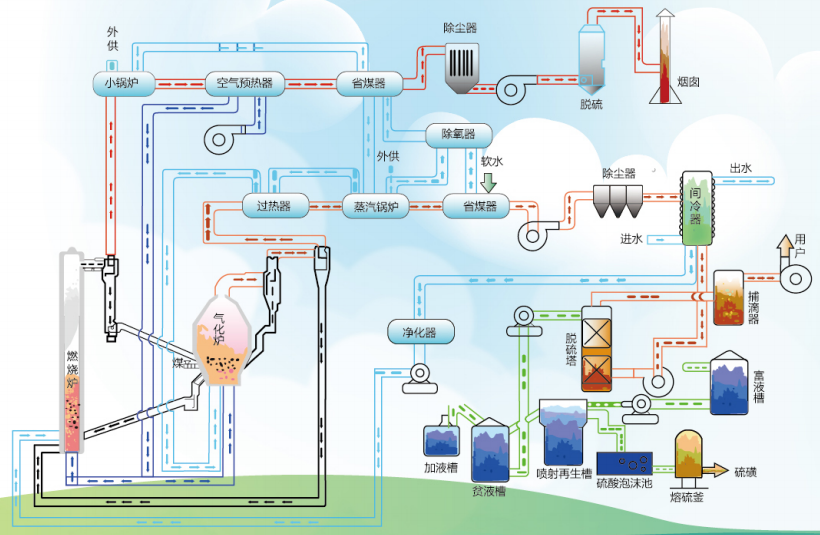

Technical background:

Coal gasification combined with directly coal gas combustion isone of most effective ways for energy saving of small andmedium-sized kilns for building materials and metallurgy etc.Fixed-bed gasifier is widely used by using lump coal to supplygaseous fuel for kilins in China. However, the coal gas produced this way is of low heating value (~1200kcal-Nm-3). Due to the fact that the amount of flue gas produced from coal gas combustion is high, the thermal efficiency of kilns is only about 30% and the thermal fficiency can be raised by increasing coal gas heating value. Moreover, lump coal only accounts for about 20~30% of coal in China, resulting in an increase price for lump coal and coal gas production costs. Thus, it is necessary to develop more secure gasification technology with higher thermal efficiency suitable to small sized coal for medium caloric coal gas production. Compared to traditional fixed bed coal gasifier, great circulation crushed coal gasification technology can provide higher caloric coal gas with the cogeneration of steam. In addition, the technology can efficiently tilize low-rank small sized coal.

Great circulation crushed coal gasification technology fills the technology gap in the almospheric coal gasifier to produce medium calorific value coal gas without pure oxygen and enriched oxygen. The 1000 Nm3-h-1 pilot has won the Hebei province scientific and technological achievements appraisal and the technology has transcended the international technical !level about 5~10 years, The world' s first application of the technology is expected to be comissioned in 2x12 kNma.h-1 Shanxi Xinhua industrialization project in 2015.

Technical advantages:

Particle size <10mm, low-rank crushed coal( lignite,bituminous coal, etc) as feedstock; Compared with fixed bed gasifier using high quality lump anthracite, the low-rank crushed coal price is low;

Atmospheric operation, without pure oxygen and enriched oxygen gasification, full recovery and

utilization of waste heat;

Stable and easy operation;

No phenol water disposal, no tar disposal, sulphur and ash as byproducts;

Medium calorific value coal gas (LHV: 1800~2200kcal.Nm-3 );

Ash carbon content<5%, higher thermal efficiency(up to 85%).

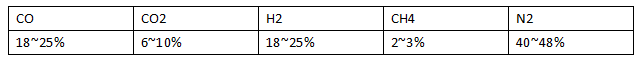

Typical gas composition:

Gas production rate: >2.5Nm3.Kg-1; gas calorific value: 1200~1600kcal.Nm-3; ash carbon content: <5%